Tech; Electric Fan Install

Return to page 1 of fan install

|

|

|

This is the suggested mounting method for the temp sensor by Flexalite.

Because of the hollow tube for the sensor I was afraid of crushing it

rendering it useless and at the track would see a puff of steam at redline

shifts occasionally. Did have the hose pop off one day after a bit of

highway testing.

UPDATE Not happy with the sensor issues I looked for the easy way out rather than a new controller/sensor.

|

|

UPDATE

Spring 04

I now have the sensor on the exterior of the rad against the frame. This is the location I tested it in to see if it would work. After small adjustment of the "fan on" temp it works faultlessly. No issue with steam or blow offs of the rad hose anymore. .

Temp Sensor is now moved to the bottom of the rad out of site with the ties trimmed flush.

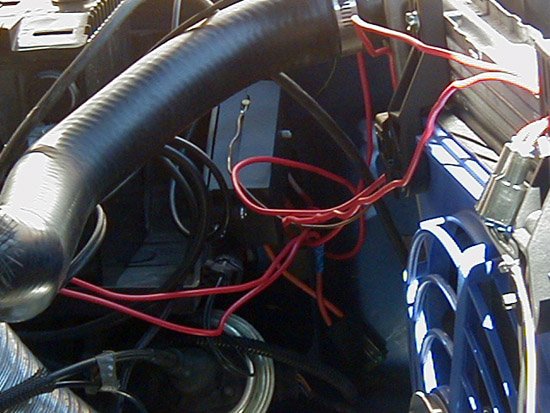

With everything secured in place time to test, with the engine running now. You want to make sure of no leak at the temp. probe/rad hose connection (alternative better) and that it comes on at the desired temp. I want mine to come on at 185 degrees approx

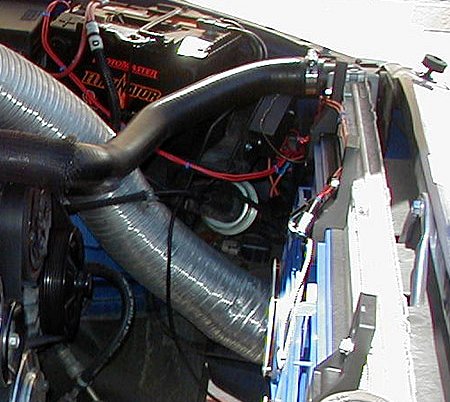

Trimmed n Cleaned up

Finished View

Since these pics, the mounting brackets on top have been cut flush with the top of the rad and the wires have all been run from under the rad instead of across the top

The view without the shroud is dramatic compared to before

PS. If you are wondering what I did with the washer fluid bottle and pump, I removed it. Now wiper motor or linkage is under the cowl either so no point having washer fluid. The truck is fair weather only.